A brief discussion on the application of carbon fiber in the field of electronic

2024-06-16 / tech

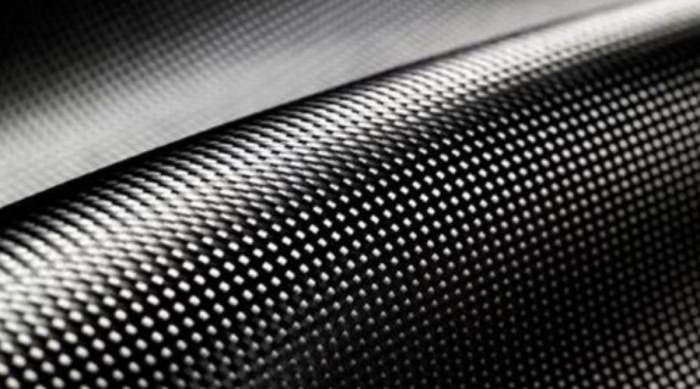

Electronic 3C is a term we often hear and encounter in our daily lives, generally referring to computers, communication, and consumer electronics, covering all aspects of life and work. As technology continues to advance, people's performance demands and standards for the user experience of 3C products are also constantly rising. Lightweighting has become an important development trend for electronic products, and carbon fiber, as a new type of high-performance material, has actively participated in the research and application of lightweighting technology in the 3C field.

Meeting design upgrade needs

The casing of electronic 3C products is the most direct part to protect the body, and it also has a significant impact on the product's heat dissipation, weight, aesthetics, and user experience. Nowadays, consumers' demands for personalized and diversified products have prompted 3C products to not only continuously improve performance and add functions but also to become increasingly "competitive" in appearance. Traditional materials used for casings can no longer meet the current lightweight, miniaturized, and complex requirements of 3C device casings, while the advantages of carbon fiber composite materials, such as high strength, high modulus, low density, low thermal expansion coefficient, and corrosion resistance, make them the preferred material for casing structures.

Advertisement

IBM, as a pioneer brand of personal computers with a history of over a century, was the first to use carbon fiber composite materials in laptop computers. In 1998, the IBM 600 model laptop was launched globally, setting off a trend of "minimalist" laptop appearances. Subsequently, major brands followed suit, starting to focus on the appearance of laptops, with "ultra-light and ultra-thin" high-end laptops and tablets designed based on carbon fiber composite materials becoming the trend pursued by the young consumer group at that time. Among them, the most representative are the Dell XPS series, Lenovo Thinkpad X series, and some high-end product lines of Sony and HP. Currently, casing structures made of carbon fiber materials have been widely applied to many mainstream brand laptops.

Adapting to new manufacturing processes

While personal computers, mobile phones, and other 3C products are moving towards becoming smaller, televisions, monitors, and the like are going in the opposite direction, challenging the trend by becoming larger. However, lightweighting and convenience are indeed their unified goals.Entering the twentieth century, LCD televisions, known for their ultra-thin form, gradually became the mainstream, and now in home decoration design, the "TV wall" is also widely favored. As ultra-thin TVs become larger, higher requirements are placed on the rigidity and stiffness of the body back panel materials. Carbon fiber composite materials, with their advantages of high strength and good rigidity, are naturally applied. It is reported that Jiangsu Aosheng Composite Material Technology Co., Ltd. has cooperated with a well-known domestic TV brand to study the forming process of carbon fiber back panels, surface treatment processes, and rigidity indicators. The scheme adopts a 3K appearance texture, and the inner layer uses UD unidirectional prepreg for laminated design, with a weight reduction effect of more than 50%, and other tests also meet the application standards. It is believed that in the future, carbon fiber composite materials will be widely used in outdoor large display devices and film and television shooting equipment.

With the rise of folding screen mobile phones, carbon fiber composite materials have also found new application points in the folding screen of mobile phones due to their many advantages. The screen support structure and hinge made of carbon fiber composite materials are thin and light, and can withstand bending and folding. According to tests, they can withstand 100,000 bending and opening and closing. In recent years, leading mobile phone brands have started to design and develop folding screen products, and Zhongfu Shenying has established a preliminary cooperation communication mechanism with major mobile phone brands for folding screen projects. Looking at the development prospects of folding screen mobile phones, it will bring a new growth point for the application of carbon fiber composite materials in the 3C field in the future.

Exploring all-round functional applications

In addition to the advantages and applications of carbon fiber composite materials mentioned above, carbon fiber composite materials also have special properties such as conductivity, thermal conductivity, strong X-ray penetration, and electromagnetic wave absorption.

It is reported that Apple's iPad and Minipad tablet series are popular among young consumer groups because they have some functions of notebook computers, are convenient to carry, and have a good user experience. The positioning of this series of products is mainly towards entertainment functions, so Apple is persistent in pursuing the sound effect. Therefore, their R&D personnel have applied carbon fiber composite materials to the design of the resonator, which can not only make the sound quality more mellow but also achieve a three-dimensional stereo effect.

With the popularity and popularity of flat mobile phones and tablet computers, various types of "mobile phone cases" and "tablet protectors" have also emerged. The role of these protective equipment has gradually evolved from the initial anti-fouling and anti-scratch to beauty and personality, and now it has started to develop towards stronger functionality. Products that are purely for beauty and affect signal reception, cause body heating, increase body weight and volume have been gradually eliminated by the market. Protective equipment made of carbon fiber composite materials that are more "invisible" and durable, and maximize the advantages of 3C products, are becoming mainstream.As a new type of high-end, high-performance material, carbon fiber composite materials are gradually stepping down from the "pedestal" and permeating every aspect of our lives. Currently, the production costs and processing techniques of carbon fibers may limit their full potential. It is believed that with the continuous development of the domestic carbon fiber industry and the expansion of research and development fields, carbon fiber composite materials will not only be deeply applied and develop in the 3C sector but also in various other fields.

Comment